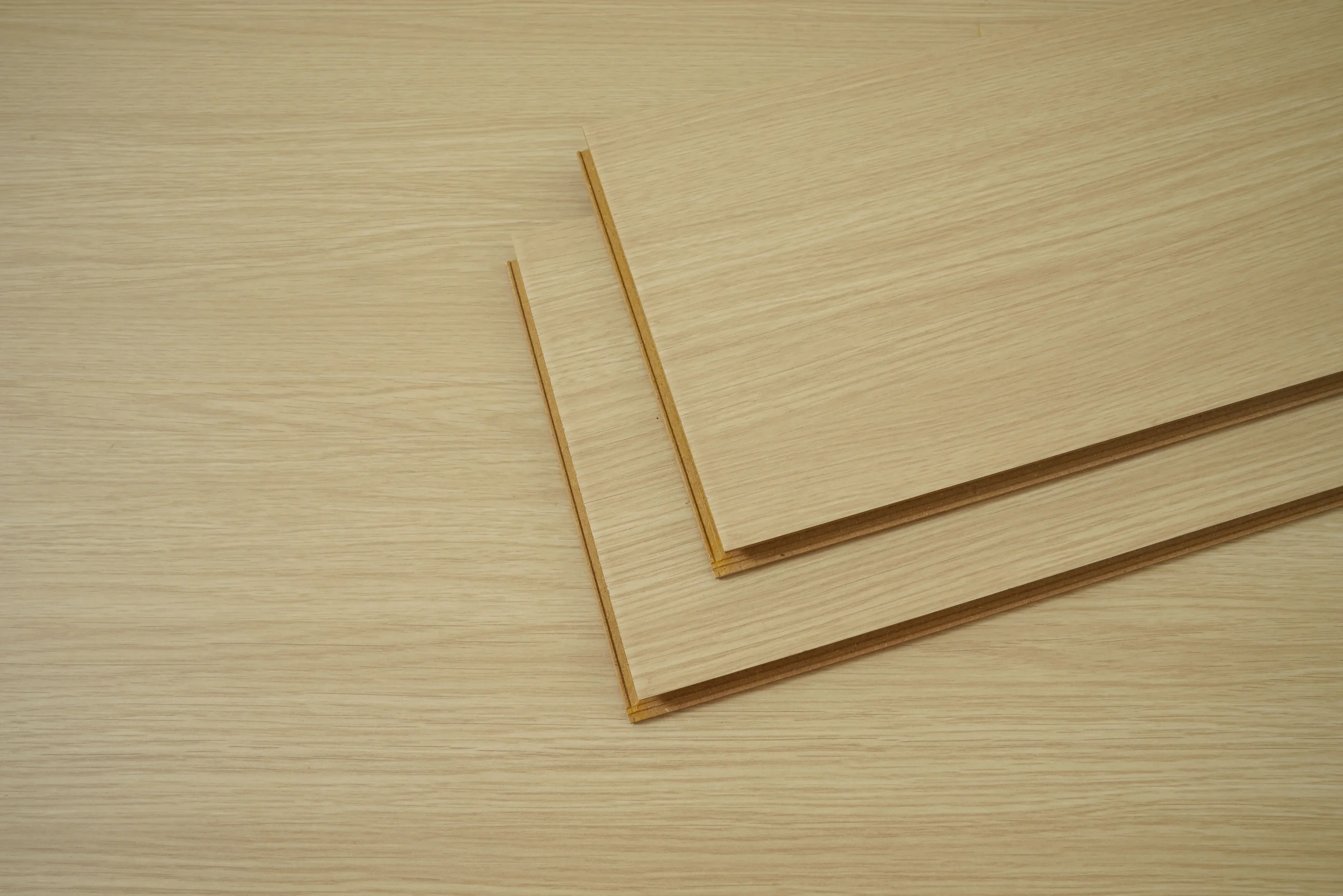

When it comes to modern flooring solutions, laminate continues to be a top choice—offering an outstanding blend of affordability, visual appeal, and quick installation. But if you’ve ever browsed catalogs or walked through a showroom, you’ll notice there are dozens of laminate types—and some hold up for decades while others fade or warp in just a few years. Why is that? We break down the key factors that define durability and highlight how industry leaders like YEHUI Flooring engineer products that stand the test of time.

What Defines the Durability of a Laminate Floor

Wear Layer Strength and Abrasion Class (AC Rating)

The wear layer is the transparent, protective shield atop the decorative design. Think of it as the armor of your laminate. Standard residential laminates typically carry an AC3 rating, suitable for moderate home use. At YEHUI, we go beyond the norm. Our products frequently meet AC4 and AC5 standards—levels certified for commercial environments such as schools, retail spaces, and offices. The difference is measurable: While AC3 laminate is suitable for general residential use, AC4 and AC5 ratings are certified for commercial environments, indicating a much higher resistance to abrasion and traffic.

High-Density Core and Moisture Resistance

The heart of laminate flooring is its core. High-density fiberboard (HDF) is the go-to material, but not all HDF is equal. A denser core resists swelling from moisture intrusion. YEHUI sources clean, uniform wood fiber, avoiding the bark-heavy blends. That detail matters: cores made with fresh fiber and consistent resin bonding will resist warping during seasonal humidity swings.

Joint System and Edge Sealing Technology

If you’ve ever seen gaps appear in a laminate floor after a few winters, that’s usually because of the joint system. Traditional flat joints can shift when the board expands. Modern solutions like YEHUI’s dual-groove locking systems keep boards tight. Some models even come with wax-sealed edges that slow down water absorption. It’s a small feature, but it extends the lifespan, especially in moisture-prone areas like kitchens and entryways.

How Do Different Laminate Constructions Compare

Standard Laminate with HDF Core

This is the backbone of the laminate market. A balanced structure of wear layer, decorative film, HDF, and backing layer. YEHUI’s LZ90 series, for example, is built for importers who want stable supply and reliable performance without pushing prices too high. These are the types you’ll find in residential projects where value and durability are both priorities

Water-Resistant Laminate with Enhanced Seal

Over the last five years, water-resistant laminate has become a buzzword. These floors use improved edge sealing and moisture-repellent coatings on the core. YEHUI’s updated Water-Resistant laminate series tackles one of the industry’s longest complaints: once laminate swells from water, it can’t be repaired. Adding that extra sealing buys time and keeps the floor looking new longer.

Decorative Parquet Laminate with Stable Structure

Sometimes longevity isn’t only about resisting scratches. It’s about staying stylish even after a decade. Decorative parquet laminate, like YEHUI’s parquet designs, combines visual appeal with a reinforced HDF base. For buyers in markets like the Middle East who appreciate intricate patterns but don’t want the price or instability of real wood parquet, this type delivers the best of both worlds.

Why Does the Choice of Raw Materials Matter

Sourced Wood Fiber from Sustainable Forests

Quality begins with sourcing. YEHUI prioritizes wood fiber from sustainably managed forests—ensuring not only environmental responsibility but also superior core integrity. They emphasize traceability—selecting logs from regions with sustainable forest management. This isn’t only a marketing claim. Wood that’s been stored and transported correctly keeps its natural strength. Poorly sourced fiber? It leads to soft cores and reduced strength.

Consistent HDF and MDF Quality Control

In the flooring industry, one bad batch of HDF can ruin a reputation. That’s why consistency in density and resin distribution matters. YEHUI’s factories in Zhejiang and Shandong keep a tight grip on moisture balance during production, reducing the risk of swelling once the floor is shipped overseas.

Eco-Friendly Adhesives and Surface Coatings

Longer life also means safer life. Using SGS-certified adhesives with low formaldehyde emissions makes the boards not only durable but healthier for families. It’s worth noting that formaldehyde release is one of the top questions asked by European buyers today, so certifications directly connect to business longevity too.

What Role Does Manufacturing Technology Play

Precision Cutting and Moisture Balance Control

A well-cut board clicks together neatly and holds steady. YEHUI’s lines use advanced saws and sanders that keep tolerances within fractions of a millimeter. Add to that a focus on balanced moisture levels before boards leave the plant—too dry and they’ll crack, too wet and they’ll swell in transit.

Advanced Surface Treatment and UV Coating

Surface treatment isn’t just about shine. UV-cured coatings increase scratch resistance and color stability. A laminate floor with high-quality coating won’t fade even in rooms with a lot of sunlight. That’s one reason why YEHUI’s decorative layers keep their look for years without the dull haze you see in lower-end products.

Quality Checks from Base Layer to Final Finish

Every YEHUI product undergoes automated and manual inspection.That level of detail is unusual but it pays off. It means fewer hidden defects, fewer returns, and more repeat buyers in overseas markets.

How Can Design and Style Impact Longevity

Texture and Embossing That Reduce Visible Wear

Laminate with embossed surfaces does more than look realistic. Textures hide scratches and small dents, extending the time before a floor looks “used” Oak grain embossing is one of YEHUI’s most requested finishes for this reason.

Color Options Customized for Market Demands

In regions like Central Asia, warm walnut tones sell quickly, while lighter gray shades trend in Europe. YEHUI provides customization services. This responsiveness doesn’t just help distributors sell—it keeps floors in style longer, reducing the chance a project feels dated in a few years.

Decorative Layers with Fade-Resistant Prints

Printing technology has advanced. High-resolution films now mimic stone, metal, or exotic wood without fading. With UV-stable inks, YEHUI’s laminate layers resist color washout even in sunny rooms.

What Certifications Show Reliable Performance

European Abrasion Standards AC3 to AC5

Buyers often ask: what’s AC4 or AC5 anyway? These are European standards that measure how many cycles a floor can withstand before showing wear. A floor rated AC4 survives at least 4,000–6,000 cycles of abrasion. That’s a big leap from AC3, which caps around 2,000–4,000.

SGS and ISO Quality and Environmental Labels

YEHUI maintains ISO9001 and ISO14001 certifications, along with SGS-tested adhesives. These are not just badges for marketing—they’re proof of our commitment to quality, consistency, and eco-compliance. which importers in Europe and North America demand.

Formaldehyde-Free and Low-VOC Compliance

It’s no secret: consumers worry about air quality. Low-VOC, formaldehyde-free boards are more than a trend. They’re often a requirement in tenders and contracts. YEHUI’s investment in net-aldehyde technology keeps them ahead of these demands.

When Should Buyers Consider Each Type

Cost-Effective Options for General Housing

For large housing projects, the LZ90 series standard laminate offers a balance of durability and price. It’s a workhorse product—easy to source in bulk and consistent in quality.

Premium Laminate for Long-Term Projects

Where longevity and low maintenance are critical, our AC5-rated waterproof laminates are the ideal choice. They carry higher upfront cost, but they extend service life by years, reducing replacement expenses later.

Parquet and Patterned Styles for Aesthetic Needs

Not every project is about cost. Hotels, offices, or upscale housing developments often specify parquet-style laminate for its visual impact. YEHUI’s parquet laminate fills this niche, without the drawbacks of solid wood—blending beauty with resilience.

The long lifespan of flooring stems from the combination of premium materials (HDF, wear-resistant layers), advanced craftsmanship (lock systems, wax sealing), and stringent quality control—areas in which YEHUI excels.

الأسئلة الشائعة

Q1. How long can I expect a laminate floor to last?

A: Most standard laminate floors last 10–15 years. Higher-grade products like AC5-rated boards, especially with water-resistant cores, can exceed 20 years with proper care.

Q2. Is laminate flooring really eco-friendly?

A: Yes, when manufacturers use wood fiber from sustainable forests and low-VOC adhesives. YEHUI, for instance, prioritizes certified raw materials and SGS-tested resins to reduce environmental impact.

Q3. What’s the difference between laminate and engineered wood?

A: Laminate uses a printed decorative layer over HDF, while engineered wood has a real hardwood veneer on top of plywood or HDF. Laminate is usually more affordable and scratch-resistant, but engineered wood offers the authentic look and feel of real timber.